The Structure and Production Process of Rubber Conveyor Belts

The Structure and Production Process of Rubber Conveyor Belts

Rubber conveyor belts are the backbone of material handling systems across industries like mining, agriculture, and manufacturing. Their durability, flexibility, and load-bearing capabilities make them indispensable. In this blog, we’ll break down their key structural components and walk you through the step-by-step production process,so you can appreciate the engineering behind these workhorses.

Scelerisque vulputate

Urna suspendisse parturient suspendisse imperdiet egestas faucibus auctor nascetur volutpat torquent proin parturient ultricies senectus dolor suspendisse amet dis vel adipiscing a elit mus. Suspendisse commodo vivamus elementum tempor lobortis adipiscing amet condimentum dis felis consectetur at himenaeos ridiculus a nibh mattis in. Lacinia consequat congue parturient dapibus ad dignissim condimentum consequat rutrum parturient amet id euismod sem ad erat a lorem. Scelerisque sociosqu ullamcorper urna nisl mollis vestibulum pretium commodo inceptos cum condimentum placerat diam venenatis blandit hac eget dis lacus a parturient a accumsan nisl ante vestibulum.

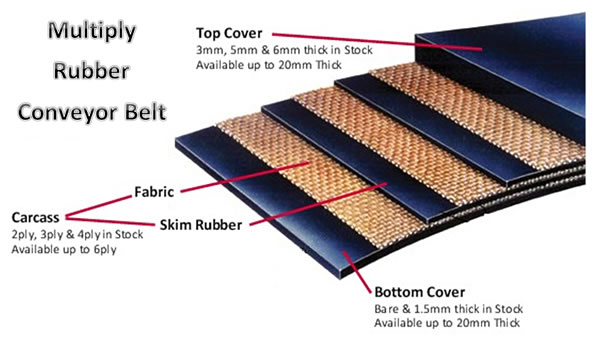

Anatomy of Rubber Conveyor Belt Structure

A high-quality rubber conveyor belt is a carefully engineered composite of multiple layers, each serving a specific purpose:

- Top Cover Rubber

- The outermost layer, designed to protect the belt from abrasion, impact, and chemicals.

- Material: Wear-resistant rubber compounds (e.g., SBR, NBR, or EPDM).

- Carcass (Reinforcement Layer)

- The belt’s skeleton, providing tensile strength and load support.

- Materials: Polyester (EP) fabric, nylon, steel cords, or aramid fibers.

- Structure: Multiple plies of fabric or steel cords embedded in rubber.

- Bottom Cover Rubber

- Protects the carcass from moisture, friction, and damage during pulley contact.

- Often made from softer rubber to reduce noise and pulley wear.

- Edge Protection

- Reinforced edges to prevent fraying and extend belt life.

- Specialized components

- Cleats, sidewalls, or profiles for inclined conveying.

- Anti-static or fire-resistant coatings for hazardous environments.

How Do We Manufacture Rubber Conveyor Belt ?

Step 1: Mixing & Compounding

- Raw rubber (natural or synthetic) is blended with additives:

- Reinforcements: Carbon black for strength.

- Vulcanizing agents: Sulfur to cure rubber.

- Anti-aging agents: Protect against UV and ozone.

- Plasticizers: Improve flexibility.

- The mixture is homogenized into sheets or pellets.

Step 2: Calendering & Fabric Prep

- Rubber sheets are pressed onto both sides of the fabric or steel cord layers using a calender.

- Layers are heat-treated to ensure adhesion and remove moisture.

Step 3: Belt Building

- The carcass (reinforcement layers) is sandwiched between the top and bottom rubber covers.

- Edges are sealed, and additional features (cleats, profiles) are added.

Step 4: Vulcanization

- The assembled belt is cured under high heat and pressure in a vulcanizing press.

- This process cross-links rubber molecules, enhancing strength, elasticity, and heat resistance.

Step 5: Quality Control & Finishing

- Belts undergo rigorous testing:

- Tensile strength and elongation tests.

- Abrasion resistance checks.

- Thickness uniformity verification.

- Edges are trimmed, surfaces are cleaned, and final markings (e.g., alignment guides) are added.

Applications of Rubber Conveyor Belts

- Mining: Transporting coal, ores, and aggregates.

- Agriculture: Moving grains, fertilizers, and produce.

- Recycling: Sorting and processing waste materials.

- Packaging: Assembly line automation.

Why Choose You Belt Industrial Co.,Ltd?

- Custom Solutions: Tailored belt designs for your industry’s demands.

- Advanced Manufacturing: State-of-the-art vulcanization and quality control.

- Global Standards Compliance: ISO-certified, fire-resistant, and food-grade options.

Ready to Optimize Your Material Handling?

Contact us today to discuss your conveyor belt requirements—we’ll deliver strength, precision, and reliability, layer by layer.

You Belt Industrial Co.,Ltd – Engineering Excellence in Every Belt.